- Products

-

- Application

- Contact us

Variable Speed Drives

Home » Application

Service factor is well defined by NEMA MG-1, sections of which are easily referred to. While it has been used as a marketing tool in the 440 NEMA frames and smaller range, It is not purely a marketing tool, it is by definition, the difference between temperature rise against name plate conditions, and the maximum allowable temperature rise against the name plate ambient temperature without exceeding thermal limits of the motor's insulation system.

For 3-Phase AC machines

Horsepower = hp, Motor Current (amps) - I, Voltage = E, Efficiency = EFF, and Power Factor = PF

I = (746 * hp) / (sqrt3 * E * EFF * PF)

For 3-Phase AC machines

Horsepower = hp, Motor Current (amps) - I, Voltage = E, Efficiency = EFF, and Power Factor = PF

I = (746 * hp) / (sqrt3 * E * EFF * PF)

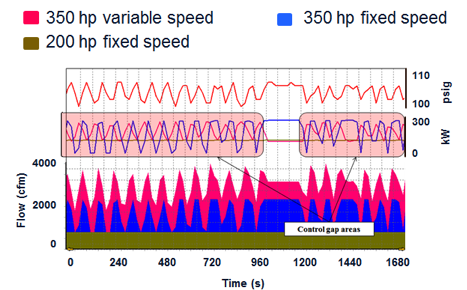

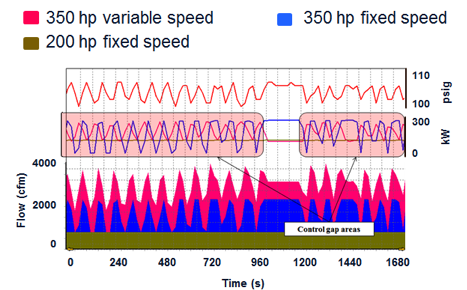

Figure 6 shows a system which exhibits a control gap between the variable speed drive compressor and one base-load compressor. In this system there was one fixed speed 350 hp compressor, one variable frequency 350 hp compressor, and one 200 hp fixed speed compressor. This system did not have a master controller for all the compressors. Figure 6 highlights a period where the medium load unit (200 hp fixed speed compressor) was operating fully loaded. This consequently resulted in multiple periods where the variable speed drive compressor and the same sized base-load compressor were cycling between load and unload together producing a fluctuating pressure of 8 psi and an uncharacteristically high specific power (kW / 100 cfm) for the facility.

In cement plants, some big power equipments run in low load in most time during production. Air/water flow demand is controlled by adjustment valve opening or damper. Disadvantages of this adjustment mode is:

- Speed of motor and fan/pump is high. Power wasting is serious.

- Atomization level is low. Precision of manual adjustment is low.

- Motor starts directly. Big start current brings impact on power grid. Power factor is low.

- Mechanical impact is big during starting. Lifetime of equipments is short.

- Noise is big. Fine dust pollution is serious.